Restore Concrete Structures

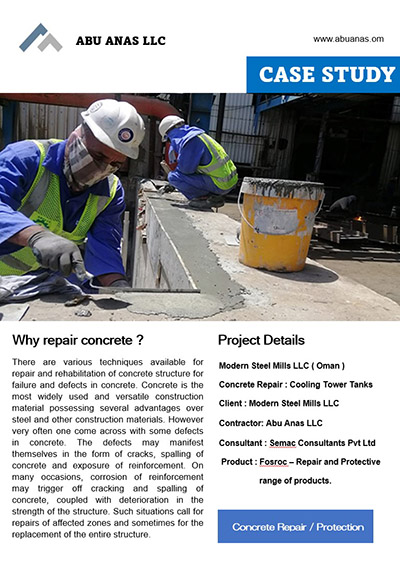

Concrete restoration is a process of repairing old and damaged concrete. Restoring concrete helps the structure return it to its original appearance. One of the biggest advantages of concrete restoration is that it’s less expensive than a new construction.

Why do we need to strengthen concrete structures?

Concrete strengthening is required for several reasons, including

To improve structural capacity: In some cases, concrete structures may need to be strengthened to improve their capacity to carry additional loads or to support new or revised design requirements. This is often necessary for older buildings or bridges that were not designed to current standards, or for structures that have been damaged or have degraded over time.

To repair or prevent damage: Concrete structures may become damaged due to a variety of factors, such as environmental exposure, inadequate design or construction, fire, or excessive loading. Strengthening the concrete can help to repair the damage, prevent further damage, and extend the life of the structure.

To enhance durability: Concrete structures can be vulnerable to various types of degradation, such as corrosion of reinforcing steel, cracking, and spalling. Strengthening the concrete can help to enhance its durability, reduce the risk of damage, and improve its performance over time.

To increase seismic resistance: In areas prone to earthquakes, concrete structures must be designed and constructed to withstand seismic forces. Strengthening the concrete can help to improve the seismic resistance of the structure, reduce the risk of damage, and ensure its continued functionality after an earthquake.

Different methods used for concrete strengthening.

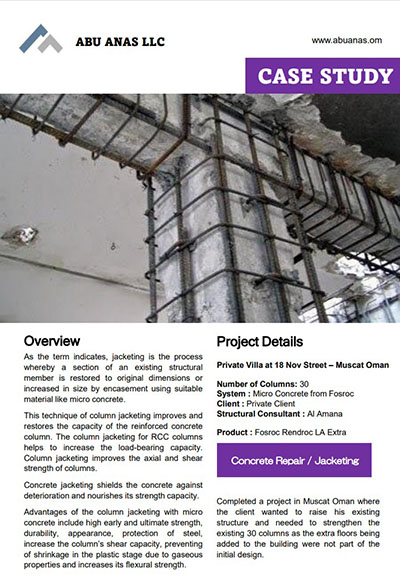

Concrete jacketing is a type of concrete repair method that involves encasing an existing concrete structure into a new layer of concrete. The new layer of concrete acts as a protective “jacket” for the existing structure, providing additional strength and stability.

Concrete jacketing is commonly used to repair concrete columns or beams that have become structurally unsound due to corrosion of the reinforcing steel or other types of damage. The new concrete jacket is cast around the existing structure and connected to it through mechanical fasteners or bonding agents. The thickness of the jacket is designed to provide the necessary reinforcement to the structure.

This method of repair has several advantages, including the ability to increase the strength of the existing structure without the need for complete demolition and replacement, and the ability to restore the original appearance of the structure. Concrete jacketing is also a cost-effective solution for many types of concrete repairs.

Concrete cutting for restoration refers to the process of removing damaged or unwanted portions of concrete structures in order to prepare the surface for repair or renovation. This process is commonly used in building restoration and rehabilitation projects, as well as in the preparation of concrete surfaces for new construction or additions.

Concrete cutting can be accomplished using a variety of tools, including saws, drills, and jackhammers. The choice of tool and cutting method will depend on the specific requirements of the job, such as the size and shape of the area to be cut, the type of concrete, and the desired finish.

Concrete cutting is a skilled and dangerous task that requires specialized training and equipment and it’s important to take appropriate safety precautions and follow safety regulations to minimize the risk of injury and protect the surrounding environment.

Concrete strengthening with carbon fibers and strips is a method of enhancing the strength and durability of concrete structures by adding carbon fiber reinforcement. The process involves attaching carbon fibers or carbon fiber strips to the surface of the concrete.

Carbon fibers are strong and lightweight, and they can provide significant reinforcing benefits to concrete structures. They are especially effective in improving the tensile strength of concrete, which is a key factor in preventing cracking and collapse.

In the case of surface-mounted carbon fiber reinforcement, the fibers are attached to the concrete using a special adhesive or epoxy. The fibers are arranged in a specific pattern to provide maximum reinforcement, and they are overlapped to ensure complete coverage.

Concrete strengthening with carbon fibers and strips is a cost-effective solution for improving the structural integrity of existing concrete structures.

This method of reinforcement is commonly used in a variety of applications, including bridges, buildings, and industrial structures, and it can provide significant benefits in terms of increased strength and longevity, improved safety, and reduced maintenance costs.

Concrete stitching is a type of concrete repair method that involves inserting steel/carbon fiber reinforcement into cracks in concrete structures in order to stabilize and reinforce the damaged area. The reinforcement is inserted in the form of steel rods or carbon rods, and it is anchored at both ends of the crack to provide a continuous connection across the damaged area.

Concrete stitching is commonly used to repair cracks in concrete beams, columns, and slabs that have become weakened over time or due to environmental factors such as temperature changes, seismic activity, or corrosion. The stitching process is typically performed by drilling holes at either end of the crack and inserting the steel reinforcement, which is then anchored in place.

One of the main benefits of concrete stitching is that it is a cost-effective and non-disruptive method of repairing concrete structures. It does not require the removal of the damaged concrete, and it can be performed while the structure is still in use.

In addition, concrete stitching can be performed quickly and efficiently, with minimal disruption to the surrounding environment or the operation of the structure. It is also a versatile method of repair, as it can be used to reinforce a wide range of concrete structures, from small cracks to large structural components.

Why is Strengthening / repairing damaged concrete so important?

Safety: Damaged concrete structures can pose a significant safety risk, as they may be prone to collapse or failure. Strengthening or repairing damaged concrete can help to ensure the structural stability and integrity of the structure, reducing the risk of accidents and protecting people and property.

Longevity: Damaged concrete structures can deteriorate rapidly if left unrepaired, leading to further structural damage and increasing the likelihood of collapse. By repairing or strengthening damaged concrete, the structure can be restored to its original condition and the rate of deterioration can be slowed, extending the life of the structure.

Aesthetics: Damaged concrete structures can detract from the appearance of a building or structure, impacting its value and overall appeal. Repairing or strengthening damaged concrete can help to restore the original appearance of the structure, improving its visual impact and overall appearance.

Cost savings: Repairs to damaged concrete can be less expensive than the cost of replacing the entire structure, particularly in the case of large or complex structures. By repairing damaged concrete, the cost of replacement can be avoided and significant cost savings can be realized.

Functionality: Damaged concrete structures can become less functional over time, reducing their capacity to perform as intended. Repairing or strengthening damaged concrete can restore the original functionality of the structure, improving its performance and ability to fulfill its intended purpose.

In conclusion, strengthening or repairing damaged concrete is important for ensuring the safety, longevity, aesthetics, cost-effectiveness, and functionality of concrete structures. It is a crucial step in maintaining the health and stability of concrete structures and preserving their value over time.

Why a is skilled and trained applicator required for Strengthening / Repairing damaged concrete?

Concrete repair and strengthening work require specialized skills and knowledge to ensure that the repairs are performed correctly and the structure is adequately reinforced. There are several reasons why a specialized applicator is needed to carry out concrete repair and strengthening work, including:

Complex procedures: Concrete repair and strengthening procedures can be complex, and require specialized knowledge and experience to perform correctly. A specialized applicator has the training and expertise to properly diagnose the problem, develop a repair plan, and carry out the work in a manner that meets industry standards.

Materials selection: The selection of materials for concrete repair and strengthening is critical, and a specialized applicator has the knowledge and experience to select the right materials for the job. The choice of materials will depend on factors such as the type of damage, the size and shape of the repair area, and the desired performance characteristics of the reinforced concrete structure.

Proper installation: Proper installation is crucial for the success of concrete repair and strengthening work. A specialized applicator has the skills and tools to install the reinforcement materials in a manner that ensures optimal performance and durability.

We are trained and certified by most of the leading construction chemical manufacturers in Oman for concrete repairs. We possess all the required tools and equipment to carry out concrete restoration works professionally. Below is the latest addition to our range of equipment.

Slab cutter

Wall cutter with tracks

You need an applicator for concrete strengthening works because it involves complex techniques and materials that require specialized training and knowledge. Here are a few reasons why:

Understanding of Structural Behavior: A specialized applicator should have a thorough understanding of the structural behavior of concrete, including its strengths and weaknesses, and how it reacts under different loads and environmental conditions. This knowledge is essential for determining the appropriate strengthening method and materials to be used.

Knowledge of Strengthening Techniques: There are several techniques used for concrete strengthening, such as fiber-reinforced polymer (FRP) systems, concrete cutting, and jacketing. A specialized applicator is well versed about these techniques, including the pros and cons of each method, and how to apply them correctly.

Proper Surface Preparation: The surface preparation for concrete strengthening is critical to the success of the project. A specialized applicator must have the skills and knowledge to prepare the concrete surface in a way that ensures a strong bond between the existing concrete and the strengthening materials.

Some of the projects we succefully completed.

Contact us for Concrete Repairs